Polyurethane, a versatile material, has found its way into various applications, from insulation to automotive parts. One of its lesser-known but equally significant applications is in mold-making. But how does polyurethane fare when used in molds, especially when compared to other materials like silicone? This article delves into the intricacies of using polyurethane in molds.

1. The Polyurethane Advantage

Polyurethane, often abbreviated as PU, is a synthetic material known for its elasticity and durability. Its unique composition allows it to be tailored to specific applications, making it a favorite among manufacturers. When it comes to mold-making, polyurethane offers several advantages:

Strength: Polyurethane molds are known for their higher strength compared to other materials.

Cost: Generally, polyurethane comes at a low to moderate cost, making it an economical choice for mold-making.

Variety: With a wide range of hardness options, polyurethane can be used for various molding applications.

2. The Challenges with Polyurethane Molds

While polyurethane offers several benefits, it’s essential to be aware of its limitations:

Release Agent Requirement: Polyurethane molds often require a careful application of a release agent to ensure the cast material doesn’t stick.

Moisture Sensitivity: In its liquid form, polyurethane is sensitive to moisture, which can affect the curing process.

3. Polyurethane vs. Silicone in Mold Making

Silicone is another popular material used in mold-making. When deciding between polyurethane and silicone, several factors come into play:

Casting Material: If you’re casting concrete, polyurethane mold rubbers are often the preferred choice. For materials like polyurethane and polyester resins, silicone rubbers might be more suitable.

Quantity of Castings: Polyurethane molds can produce hundreds of castings, especially for materials like concrete, plaster, and wax. Silicone molds, while more expensive, can produce a large number of castings, especially for resins.

Model Material: It’s crucial to consider the material of the model or master. For instance, platinum-cured silicones might not cure properly when poured over sulfur-containing clay.

4. Practical Applications

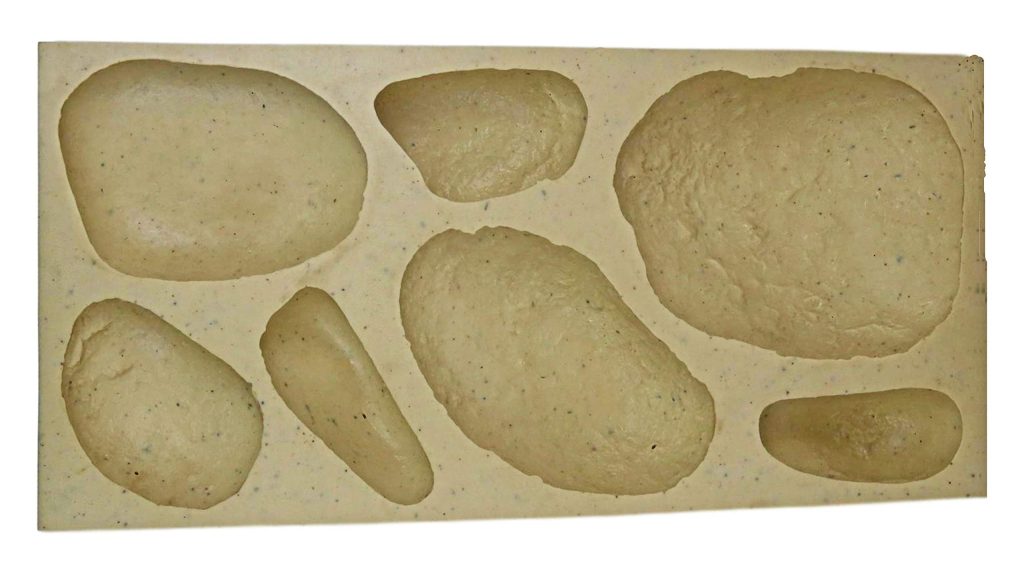

Polyurethane molds are commonly used for casting concrete, wax, plaster, and even some resins. Their durability and cost-effectiveness make them a popular choice for many manufacturers. Whether you’re creating concrete statuary, form liners, stamping mats, or other products, polyurethane molds can be an excellent choice.

Conclusion

Polyurethane, with its unique properties, offers a compelling case for its use in molds. While it has its challenges, understanding its strengths and limitations can guide manufacturers in making informed decisions. Whether you choose polyurethane or another material like silicone, it’s essential to consider the specific requirements of your project to achieve the best results.