Polyurethane rubber, a versatile and widely used material in various industries, often raises questions about its properties. One such query that frequently emerges is: Does polyurethane rubber shrink? Let’s delve deep into this topic to provide a clear understanding.

Understanding Polyurethane Rubber

Polyurethane, commonly referred to as PU, is an organic polymer known for its durability, flexibility, and adaptability. It’s used in numerous applications, from mold-making to automotive parts, due to its unique properties.

Shrinkage in Polyurethane: The Basics

Shrinkage refers to the reduction in size of a material after it has been molded and cured. In the case of polyurethane rubber, while it does exhibit some degree of shrinkage, it’s essential to understand the factors influencing this phenomenon.

Casting Size and Wall Thickness: The size of the casting and its wall thickness can influence the degree of shrinkage. Larger castings with thicker walls may experience more shrinkage than smaller ones.

Work Temperature: The ambient temperature during the curing process can also play a role. A higher temperature might lead to increased shrinkage.

Type of Polyurethane: There are various types of polyurethane rubbers available in the market, each with its unique formulation. Some might have a higher shrinkage rate than others.

Comparing Shrinkage: Polyurethane vs. Other Materials

When compared to other mold-making materials, polyurethane rubber’s shrinkage is relatively moderate. For instance:

Silicone Rubber: Silicone rubber, another popular mold-making material, has a shrinkage rate that can vary. Some high-quality silicones offer almost zero shrinkage, while others might shrink slightly.

Latex Rubber: Latex, a natural rubber, tends to have a higher shrinkage rate than both polyurethane and silicone.

Mitigating Shrinkage in Polyurethane Rubber

While some degree of shrinkage in polyurethane rubber is inevitable, there are steps that can be taken to minimize its effects:

Proper Mixing: Ensuring that the polyurethane components are mixed correctly and in the right proportions can help reduce shrinkage.

Optimal Curing Conditions: Maintaining a consistent and appropriate temperature during the curing process can help in achieving uniform shrinkage.

Using Fillers: Some manufacturers add fillers to the polyurethane mixture to reduce the overall shrinkage rate.

Practical Implications of Shrinkage

For industries where precision is paramount, understanding and accounting for polyurethane rubber’s shrinkage is crucial. For instance:

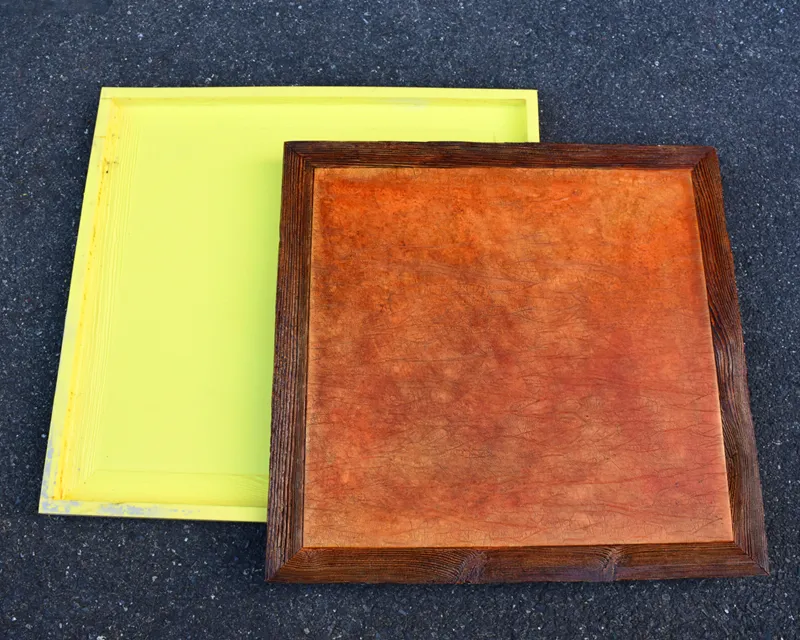

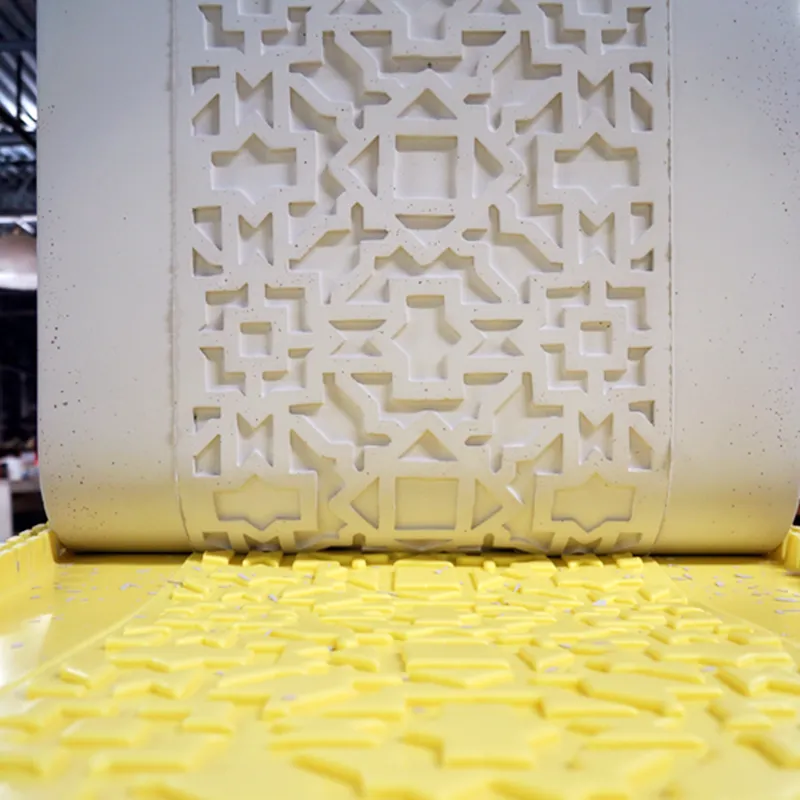

Mold Making: If a mold made from polyurethane rubber shrinks, the final cast product might not have the desired dimensions. It’s essential to account for potential shrinkage when designing the mold.

Automotive Parts: In the automotive industry, where parts need to fit precisely, any shrinkage can lead to functional and safety issues.

Conclusion

While polyurethane rubber does exhibit some degree of shrinkage, it’s relatively moderate compared to other materials. By understanding the factors influencing shrinkage and taking steps to mitigate its effects, manufacturers and crafters can achieve desired results with polyurethane rubber. As always, it’s essential to choose the right type of polyurethane for the specific application and to be aware of its properties to ensure optimal outcomes.