Description

Description:

Polyurethane Mold Rubbers are good for GRC mold making, it’s specially formulated as elastomeric material for preparing negative moulds in precast or in-situ concrete industries. Mostly used for making architectural GRC (glass reinforced concrete) elements include panels, columns heads and other elements. It consists of two parts(A&B), which after mixing, cure at room temperature to flexible, high-strength, mold rubbers.The cured material provides very high elastomeric property with sufficient hardness.

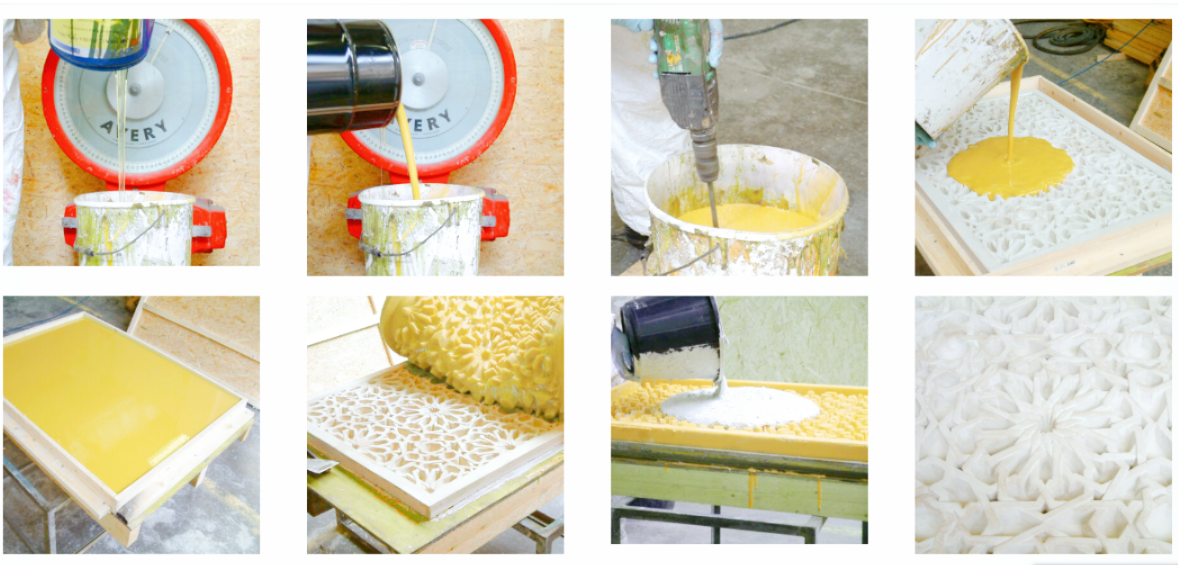

JH Polyurethane Mold Rubber to Make GRC Products Process:

Features:

What are the advantages of JH polyurethane mold rubber to make your GRC mold making ?

1.) Reusable ~ Molds can be used over and over again.

2.) Does not shrink ~ Has good abrasion resistance.

3.) It comes in a wide range of hardnesses and therefore gives long mold life.

4.) It can be poured, brushed or sprayed on to the original model.

5.) It is the most economical overall (compared to other mold rubbers).

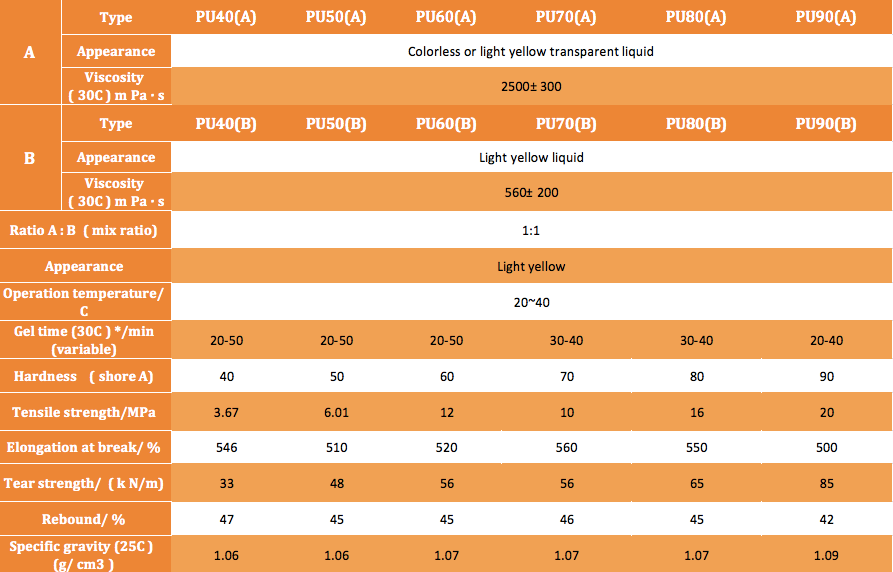

Data Sheet:

Operation Method:

Both pouring and spraying are available, and if you want to brush, we have a thickening agent to adjust the viscosity of polyurethane mold rubber for brushing.

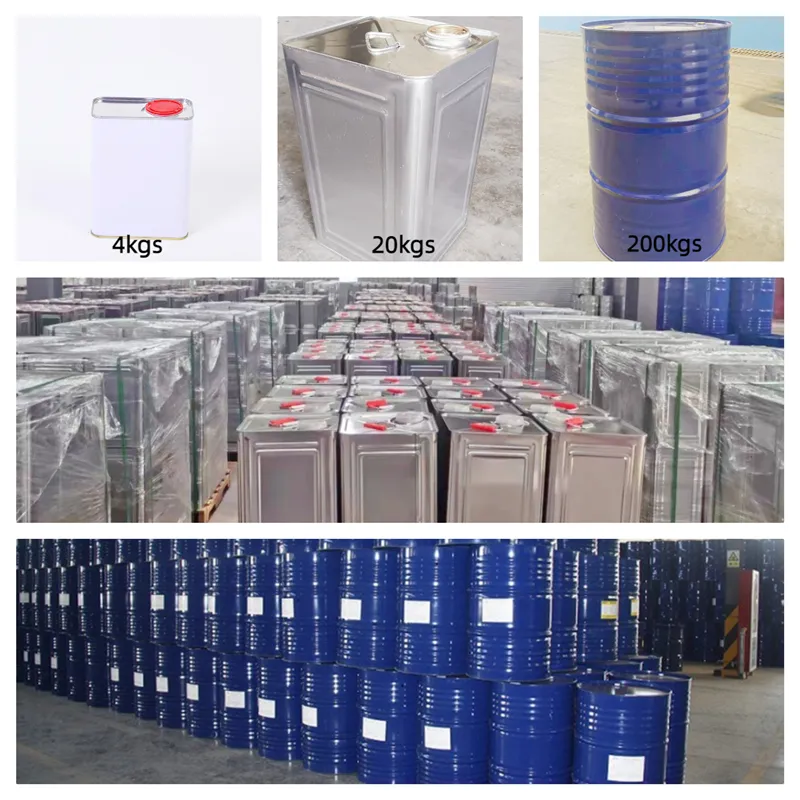

Storage:

Store in a cool and dry place. If you can’t use one drum up at a time, please inject N2. The storage time of the original packing is 6 months.

Warm Tips:

To ensure dimensional accuracy and maximum life period, moulds made of JH polyurethane rubber are preferably stored in their supporting mould under air admittance. Prolonged compression may lead to irreversible deformation. The moulds must be protected against UV irradiation and direct insolation.

Reviews

There are no reviews yet.