Polyurethane is a versatile material with a wide range of applications, from furniture finishes to protective coatings. However, when working with polyurethane, one common challenge faced by many is its tendency to adhere to various surfaces. This article explores the materials and surfaces to which polyurethane does not readily stick, providing insights for those working with this polymer.

- The Sticky Nature of Polyurethane

Polyurethane, by its very nature, is designed to adhere to surfaces, forming a durable and protective layer. This adhesive quality is what makes it an excellent choice for coatings and sealants. However, this same property can pose challenges, especially when it comes to cleanup and tool maintenance. - 2. Surfaces Resistant to Polyurethane Adhesion a. Teflon (PTFE)

- One of the most notable materials that resist polyurethane adhesion is Teflon, also known as PTFE. Teflon is renowned for its non-stick properties, making it a popular choice in cookware and various industrial applications. Laboratory equipment like beakers and spatulas made of Teflon can resist the adhesion of polyurethane, making cleanup easier.

- The Sticky Nature of Polyurethane

- b. Certain Plastics

- While polyurethane can adhere to many plastics, some specific types, like polypropylene and polyethylene, offer resistance to polyurethane adhesion. However, it’s essential to test on a small area before assuming complete resistance.

- c. Vegetable Oil

- Although not a permanent solution, vegetable oil can act as a temporary barrier, preventing polyurethane from sticking to tools. However, care must be taken to ensure that the oil does not mix with the polyurethane, as it can compromise the quality of the final product.

- Challenges and Solutions

While there are materials that polyurethane doesn’t stick to, finding a permanent solution for tools and equipment remains a challenge. Temporary measures, like vegetable oil, require regular reapplication and can be messy. On the other hand, while Teflon offers a more permanent solution, not all tools and equipment are readily available in Teflon-coated versions.

- Tips for Working with Polyurethane

Regular Cleanup: Clean tools immediately after use to prevent polyurethane from curing on them.

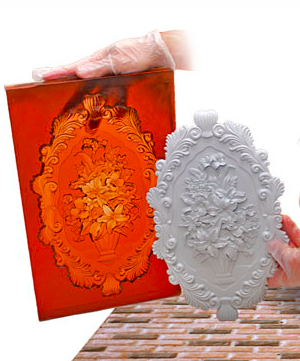

Use Release Agents: Applying a release agent to surfaces can prevent polyurethane from sticking.

Test First: Before applying polyurethane to any surface, especially if unsure about its adhesive properties, conduct a small test to check for adhesion. - .Conclusion

While polyurethane’s adhesive properties make it a valuable material in many applications, these same properties can pose challenges. By understanding the surfaces and materials resistant to polyurethane adhesion, one can make informed decisions and streamline their workflow, ensuring efficiency and quality in their projects.