Mold making is an essential process in various industries, from art and craft to large-scale manufacturing. The choice of material for the mold plays a pivotal role in determining the quality, durability, and efficiency of the molding process. Polyurethane rubber has emerged as a popular choice for mold making, and for good reasons. This article delves into the advantages of using polyurethane rubber in mold making.

1. Versatility in Hardness:

Polyurethane rubber is available in a wide range of hardness levels. This versatility allows manufacturers to choose the perfect hardness level tailored to the specific requirements of their project. Whether one needs a softer mold for intricate designs or a harder one for durability, polyurethane rubber offers the flexibility to cater to diverse needs.

2. Durability and Longevity:

One of the standout features of polyurethane rubber is its long-lasting nature. Molds made from this material can withstand repeated use without showing signs of wear and tear. This durability translates to cost savings in the long run, as there’s no frequent need for mold replacement.

3. Cost-Effectiveness:

When compared to other mold-making materials like silicones and polysulfides, polyurethane rubber tends to be more cost-effective. This affordability does not come at the expense of quality, making it an attractive option for businesses looking to optimize production costs.

4. Simplified Measurement Process:

With polyurethane rubber, there’s often no need for an accurate gram scale. This simplifies the mold-making process, reducing the chances of errors and ensuring consistent results.

5. No Need for Vacuum Degassing:

Vacuum degassing is a process used to remove trapped air from mold-making materials. With polyurethane rubber, this step is generally not required, which speeds up the mold-making process and reduces the equipment needed.

6. Superior Strength:

Polyurethane rubber boasts higher strength compared to many other mold-making materials. This strength ensures that the molds can handle the pressures of casting without deforming or breaking.

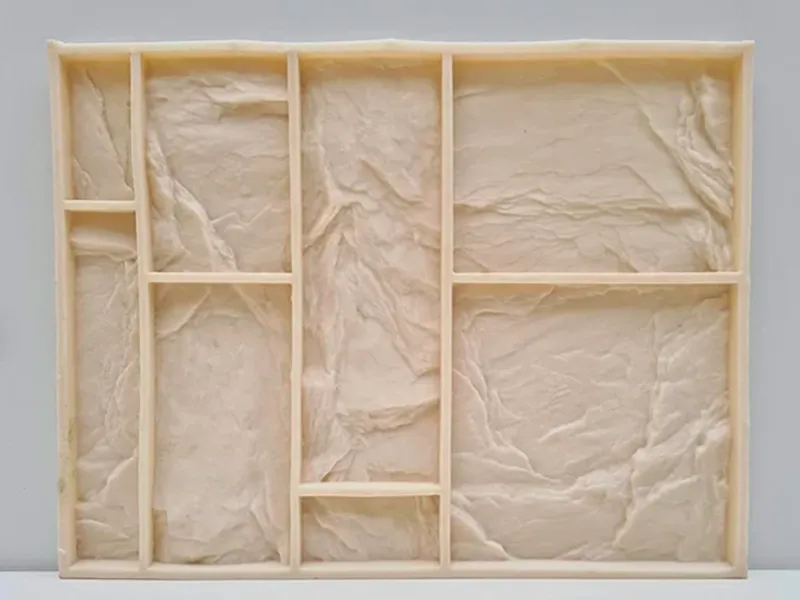

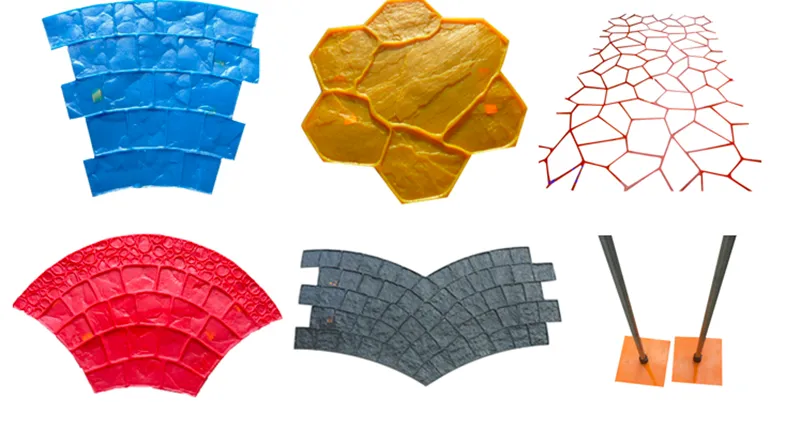

7. Wide Application Range:

Polyurethane rubber molds are versatile and can be used for various applications, from casting concrete to creating intricate art pieces. Their adaptability makes them a favorite choice across different industries.

8. Better Cost-to-Performance Ratio:

While there are cheaper mold-making materials available, polyurethane rubber offers an excellent balance between cost and performance. Its durability, ease of use, and versatility provide great value for money.

9. Environmentally Friendly:

Polyurethane rubber is made up of organic compounds, making it a more environmentally friendly option compared to some synthetic materials. This is an added advantage for businesses looking to adopt greener practices.

Conclusion:

Polyurethane rubber has carved a niche for itself in the world of mold making. Its myriad advantages, from versatility in hardness to cost-effectiveness, make it a preferred choice for both hobbyists and large-scale manufacturers. As industries continue to evolve and seek efficient and durable mold-making solutions, polyurethane rubber’s prominence is set to grow even further. Whether you’re a seasoned manufacturer or someone just starting in the world of mold making, polyurethane rubber offers benefits that are hard to overlook.