Concrete casting is an art that requires precision, patience, and the right materials. One crucial aspect of the casting process is ensuring that the concrete doesn’t stick to the mold, which can result in imperfections or even damage to the mold itself. This is where release agents come into play. This article delves into the best release agents for concrete molds, ensuring a smooth and easy demolding process.

1. Understanding the Role of Release Agents

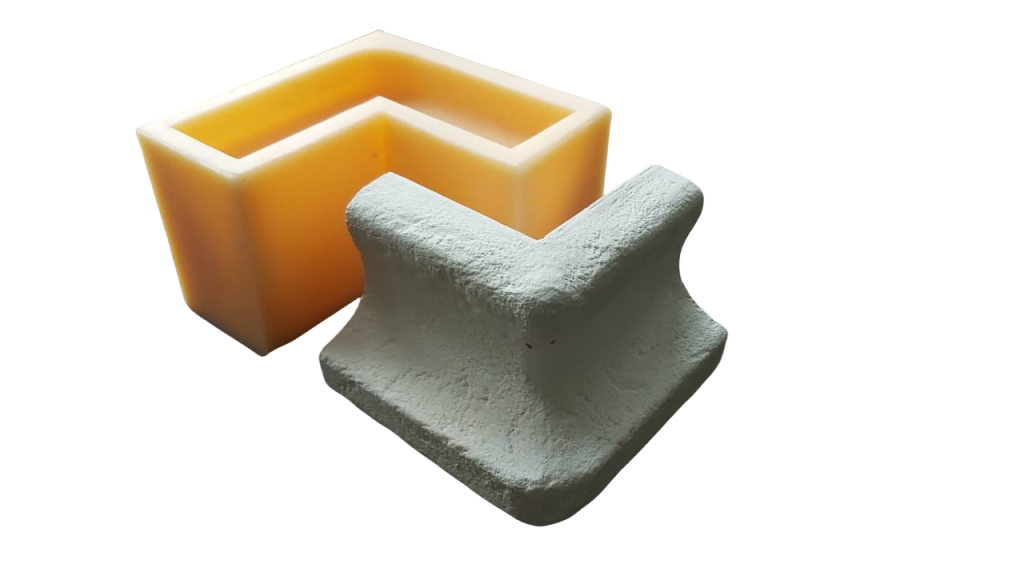

Release agents are substances applied to the inner surface of molds before pouring concrete. Their primary function is to create a barrier between the mold and the concrete, preventing adhesion and facilitating easy removal of the casted object.

2. Top Release Agents for Concrete Molds

a. PAM Cooking Spray

Surprisingly, PAM, a common household cooking spray, is one of the most effective release agents for concrete molds. A light coat on the mold’s inside ensures that the casting comes out effortlessly. However, it’s essential to apply it evenly and avoid over-spraying, which can mix with the concrete and affect its quality.

b. Wax

Wax is another popular release agent, especially for complex molds with intricate designs. It can be applied to the mold’s surface and remains there until the concrete is cast. For best results, apply the wax before assembling the mold and buff off any white residue that forms on the treated surfaces. This residue can leave marks on the finished casting if not removed.

c. Motor or Vegetable Oil

A rag dipped in motor or vegetable oil can be used as a release agent, especially when applied over a waxed surface. The key is to moisten the surface with the smallest amount of oil possible, ensuring a thin and even coat.

d. Commercial Release Agents

There are also commercial release agents available, such as Smooth-On’s AquaCon® water-based concrete release agent. While some users find other products more effective, it’s essential to test and find the one that works best for your specific needs.

3. Tips for Using Release Agents

Avoid Over-application: Using too much release agent can color the concrete or result in drips and puddles inside the mold.

Test Before Use: Always test the release agent on a small portion of the mold to ensure it doesn’t react with the concrete or the mold material.

Ensure Even Application: An uneven application can result in areas where the concrete sticks to the mold, so ensure a uniform coat.

4. Conclusion

Choosing the right release agent for concrete molds is crucial for achieving perfect castings and prolonging the life of your molds. Whether you opt for household solutions like PAM and wax or commercial products, the key is to find what works best for your specific needs and ensure proper application.