Polyurethane molds are versatile tools used in various industries, from arts and crafts to construction. The choice of material for casting these molds is crucial, as it determines the mold’s durability, flexibility, and the quality of the final product. This article delves into the materials commonly used for casting polyurethane molds and their respective advantages and disadvantages.

1. Understanding Polyurethane Molds

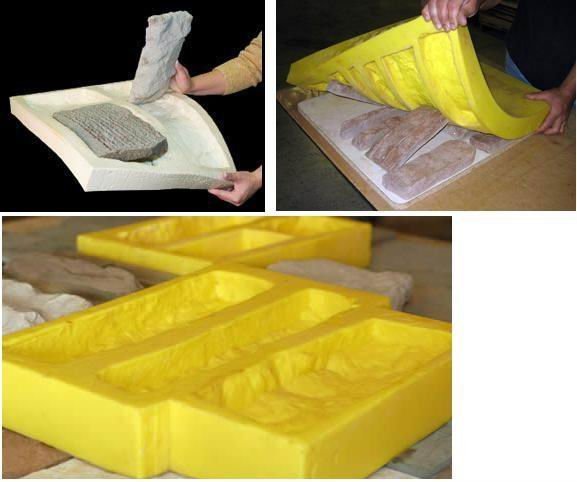

Polyurethane molds are created by pouring or injecting a liquid polyurethane material into a mold cavity. Once cured, this material takes the shape of the cavity, producing a mold that can be used to cast various materials, including concrete, wax, plaster, and resins.

2. Materials for Casting Polyurethane Molds

a. Polyurethane Rubber

Advantages: Offers higher strength, comes at a low to moderate cost, and is available in a wide range of hardness levels.

Disadvantages: Requires careful application of a release agent and is moisture-sensitive in its liquid form.

Methods: Pour, brush, spray.

b. Tin-Cured Silicone Rubber

Advantages: No release agent is needed, and it provides excellent chemical resistance.

Disadvantages: It has a higher cost, shrinks upon curing (~1%), and the cured rubber has a limited storage life.

Methods: Pour, brush, spray.

c. Platinum-Cured Silicone Rubber

Advantages: No release agent is required, no shrinkage upon curing, the cured rubber has a long storage life, and it offers excellent chemical resistance.

Disadvantages: Higher cost and curing can be inhibited by some surfaces.

Methods: Pour, brush, spray.

3. Factors to Consider When Choosing a Material

Casting Material: For example, polyurethane mold rubbers are the preferred choice for casting concrete, while silicone rubbers are often used for casting polyurethane and polyester resins.

Number of Castings: If you need to produce a large number of castings, polyurethane rubber molds might be more cost-effective. However, for limited castings with specific requirements, silicone rubbers might be the better choice.

Model Material: Some materials can inhibit the curing of certain mold rubbers. For instance, platinum-cured silicones might not cure properly when poured over sulfur-containing clay or certain plastics.

4. Conclusion

The choice of material for casting polyurethane molds depends on various factors, including the intended use of the mold, the number of castings required, and the material of the model. By understanding the advantages and disadvantages of each material, one can make an informed decision that best suits their project’s needs.