Concrete casting has revolutionized the construction and DIY world, offering endless possibilities for creating structures and art pieces. The mold material plays a pivotal role in this process, determining the finish, durability, and quality of the casted object. This article delves into the best materials for concrete molds, guiding you towards an informed decision.

1. The Role of Mold Material

The mold material not only gives shape to the concrete but also influences its texture and finish. A good mold ensures a smooth surface, precise dimensions, and a flawless finish.

2. Popular Materials for Concrete Molds

a. Wood/Melamine

Melamine, a type of wood, is one of the most commonly used mold-making materials. It offers a smooth finish and is ideal for creating flat surfaces like countertops.

Pros: Smooth finish, readily available.

Cons: Can absorb moisture if not sealed properly.

b. Rigid Foam

Rigid foam, often used as insulation, comes in various types, including Molded Expanded Polystyrene (MEPS) and Extruded Expanded Polystyrene Foam Board (XEPS). These foams can be shaped and sanded to create molds.

Pros: Lightweight, easy to shape.

Cons: Vulnerable to certain solvents.

c. Fiberglass

Fiberglass is a strong and durable material ideal for creating intricate mold designs. It can be combined with other materials like polyester auto body filler for added strength.

Pros: Durable, versatile.

Cons: Requires expertise to work with.

d. Metal

Metal molds, especially those made of steel, are used for large-scale projects where strength is paramount.

Pros: Extremely strong and durable.

Cons: Expensive and can be challenging to shape.

e. Plastic

Plastics like ABS, Acrylic, and PVC are versatile and offer a range of properties suitable for mold-making.

Pros: Variety of options, easy to work with.

Cons: Some plastics may not be as durable as others.

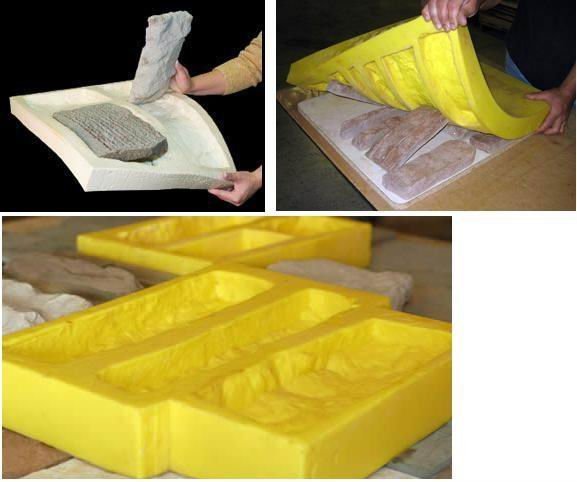

f. Polyurethane Rubber

Polyurethane rubber is a two-part casting material known for its flexibility and durability. It’s especially useful for complex shapes.

Pros: Flexible, durable. it’s the best choice for concrete and stone mold making

Cons: temperature resistance only 80degree

3. Factors to Consider When Choosing a Mold Material

Project Size: Larger projects might require more durable materials like Polyurethane rubber, metal or fiberglass.

Budget: While materials like metal and fiberglass offer durability, they can be more expensive than wood or plastic.

Desired Finish: The choice of material can influence the texture and finish of the casted object.

4. Conclusion

Choosing the right mold material for concrete casting is essential for achieving the desired results. Whether you’re a professional or a DIY enthusiast, understanding the properties and advantages of each material will help you make an informed decision.