Concrete molds play a pivotal role in shaping and forming concrete into desired shapes and designs. The choice of material for these molds can significantly impact the quality, finish, and durability of the final concrete product. This article explores the various materials commonly used for concrete molds.

1. Polyurethane Rubber

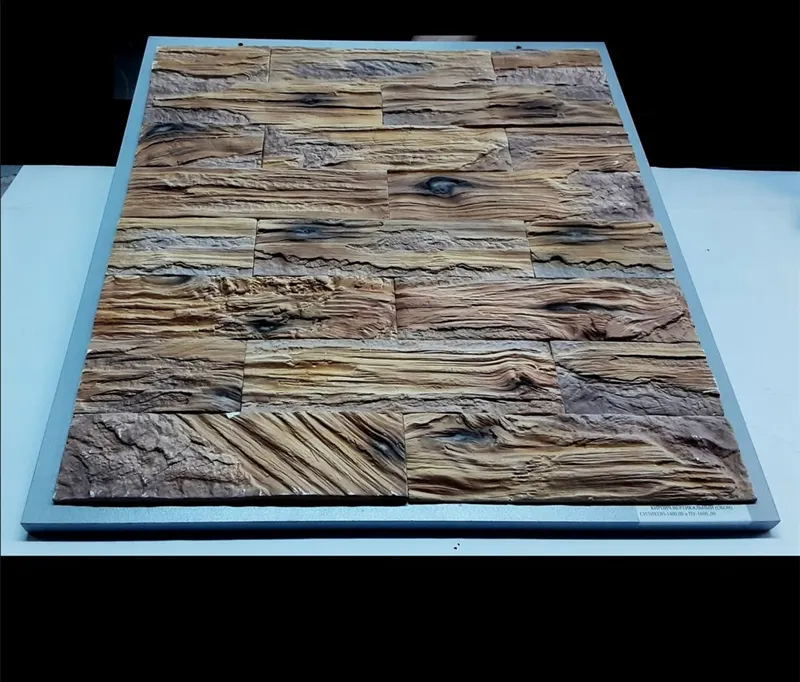

Polyurethane rubber is the most popular choice for concrete molds due to its flexibility and durability. It can capture intricate details, making it ideal for decorative concrete pieces. Additionally, polyurethane molds are resilient, allowing for repeated use without significant wear and tear.

2. Silicone Rubber

Silicone rubber molds are known for their excellent release properties, often eliminating the need for a release agent when casting concrete. They are also highly flexible, making demolding easier and ensuring a smooth finish on the concrete surface. Silicone molds are particularly favored for intricate designs and smaller decorative pieces.

3. Latex Rubber

Latex rubber molds are flexible and can stretch considerably, making them suitable for ornamental concrete pieces. They are often more economical than silicone or polyurethane but may have a shorter lifespan.

4. Fiberglass

For larger concrete casting projects, fiberglass molds are often the go-to choice. These molds are rigid and can support heavy concrete without deforming. They are durable, long-lasting, and ideal for projects that require consistent shapes and sizes.

5. ABS Plastic

ABS plastic molds are lightweight, durable, and relatively inexpensive. They are often used for making pavers, stepping stones, and other similar concrete products. The rigid nature of ABS plastic ensures consistent shapes, but it might not capture intricate details as effectively as flexible rubber molds.

6. Steel and Aluminum

In industrial settings, steel and aluminum molds are commonly used due to their strength and durability. They can withstand heavy loads and are ideal for large-scale concrete casting projects. However, they are heavier and may require machinery for handling.

Conclusion

The choice of material for a concrete mold depends on the project’s requirements, budget, and desired finish. While flexible rubber molds like silicone and polyurethane are ideal for detailed designs, meanwhile, polyurethane mold rubber, rigid molds made of fiberglass, ABS plastic, or metal are better suited for larger projects and consistent shapes. By understanding the properties and advantages of each material, one can select the best mold material tailored to their specific need