Mold casting is a versatile process that allows for the creation of intricate and detailed objects. The choice of material for mold casting can significantly influence the final product’s quality, durability, and appearance. This article explores the various materials commonly used in mold casting and their respective advantages and disadvantages.

1. Silicone Rubber

Silicone rubber is one of the most popular materials for mold casting due to its flexibility and ability to reproduce fine details. It is non-reactive, which means it won’t stick to many materials, making it ideal for complex shapes and designs.

Advantages:

High flexibility and elasticity.

Excellent detail reproduction.

Long mold lifespan.

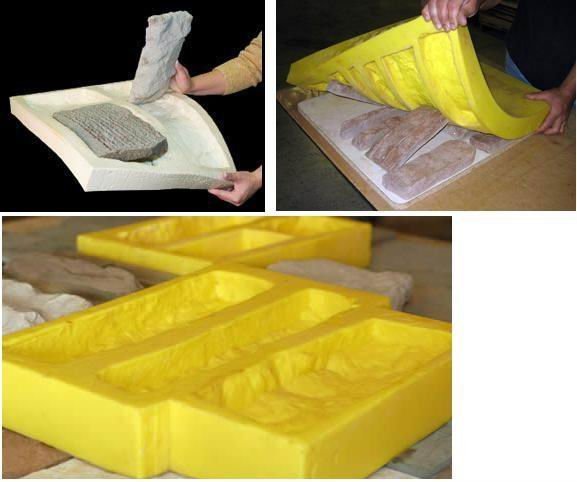

2. Urethane Rubber

Urethane rubber, or polyurethane rubber, is known for its durability and strength. It’s often used in industrial applications and can withstand more rigorous conditions than silicone.

Advantages:

Durable and resilient.

Suitable for casting various materials, including concrete, stone, GRC/GRG/GFRC and plaster.

3. Plaster of Paris

Plaster of Paris is a quick-setting material that’s been used for centuries in mold casting. It’s ideal for creating decorative items and art pieces.

Advantages:

Inexpensive and readily available.

Sets quickly.

4. Latex Rubber

Latex rubber is a natural material that can be brushed onto objects to create flexible molds. It’s often used for mask-making and decorative items.

Advantages:

Biodegradable and eco-friendly.

Suitable for casting plaster and some resins.

5. Alginate

Derived from seaweed, alginate is primarily used for life casting due to its ability to capture fine details and its safety for direct skin contact.

Advantages:

Safe for skin.

Captures excellent detail.

6. Metals

Metals like aluminum and zinc with low melting points are also used for casting. They provide durability and a distinct finish to the casted objects.

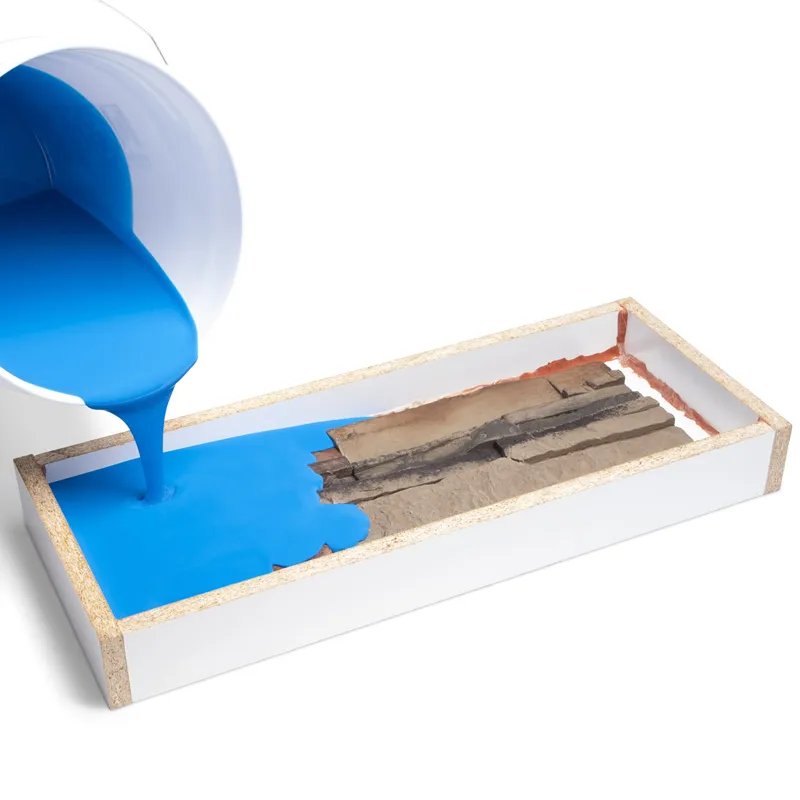

7. Resins

Resins, including polyurethane and epoxy resins, are synthetic materials used for casting objects that require durability and a smooth finish.

Advantages:

Versatile with various finishes available.

Durable and long-lasting.

8. Conclusion

The choice of material for mold casting depends on the desired outcome, budget, and specific project requirements. By understanding the properties and applications of each material, artists and manufacturers can select the best option.